August 19, 2022

August 19, 2022

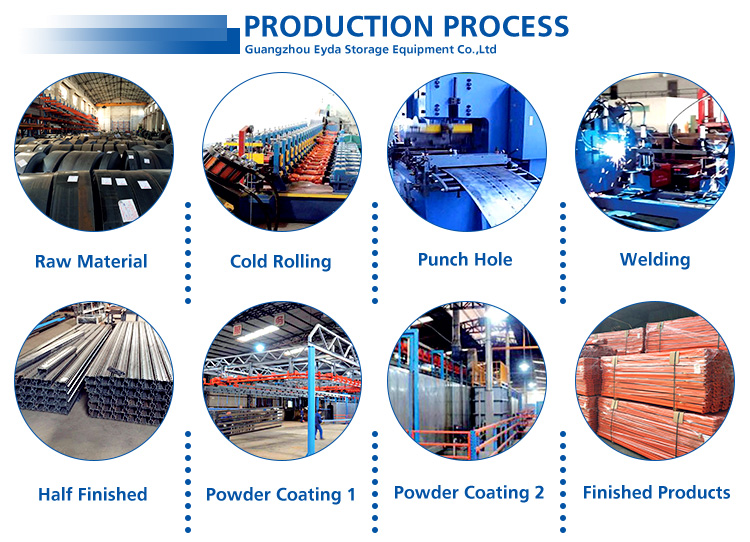

What is the production process of the warehouse racking?

August 19, 2022

August 19, 2022

Return

Return

Warehouse racking are indispensable in modern warehouse shelves. The scientific and rational use of warehouse racking can make our warehouse clean and orderly. Traditional racks include pallet racks, attic racks, platform racks, shelf racks, etc. With the rapid development of the industry, traditional shelves can no longer meet the storage needs of some enterprises. Shuttle pallet racking, automated three-dimensional warehouses, and semi-automated three-dimensional warehouses have also become a trend in the warehousing industry.

What are the production processes of our common warehouse racking?

1. Laminate process: 1. Blanking (cutting) fabric head material reinforcement; 2. Bending) layout bending head bending reinforcement rolling; 3. Assembly spot welding; 4. Plastic spraying; 5 packs.

2. Beam process: 1. Cutting beam P; 2. Phosphating; 3. Strip blanks under pendant material; 4. Punching and punching squares; 5. Punching punching teeth; 6. Bending; 7. Welding; . Spray; 9. Packaging.

3. Column process: 1. C-shaped steel forming; 2. C-shaped steel blanking; 3. Horizontal slash blanking; 4. Foot piece blanking; 5. Phosphating of each part; 6. Welding; Package.

RECOMMEND INFORMATION

-

What is the production process of the warehouse racking?August 19, 2022